INTRODUCTION

Hildebrand Marine’s engineering activities are guided by a structured, flexible design philosophy drawn from classical marine design principles as described in Ship Design and Construction, tailored to suit Hildebrand Marine’s unique requirements. Hildebrand Marine’s Corporate and Engineering mission statements guide this design philosophy which answers the questions “What do we do?” and “Why do we do it?”

What we do is iterate a number of key design elements sequentially through a “design spiral” until the design is complete. The spiral is divided into phases. Why we do design iterations is to reduce the technical risk and production rework and material waste to a minimum. This approach provides a structured definition of the engineering activities during each phase for each project, but it also allows flexibility for each Project Team to uniquely tailor the activities to suit the individual project.

PHASES

The four phases of the engineering process have been identified as (Ship Design and Construction terminology is identified in brackets [ ] ):

Concept Design [Concept Design]

Contract Design [Preliminary Design]

Functional Design [Contract Design]

Production Design [Detail Design]

The first three phases define the vessel being designed in progressively greater detail. It is important to recognize that the design process in the first three phases is continuous and that breaking it into phases simply provides a structure with convenient break points for design reviews and “go/ no go” decisions. The key elements and the basic process remain central throughout. The fourth phase translates that design into information production can use to build the vessel.

The design maturity increases during each phase. At the end of Concept Design. Engineering has identified one or more plausible designs to suit high-level requirements. Contract Design develops the vessel design enough to ensure meeting detailed mission requirements. Together, these two phases comprise basic design. At the end of basic design all major design elements are well defined, along with the system requirements. A completed Functional Design documents a fully integrated vessel. All systems, including material, have been defined and engineered. Engineering design is essentially complete at the end of Functional Design.

The fourth phase is fundamentally different. In Production Design, very little new design is done. Instead, this phase is mostly concerned with translating the design into production information for building the vessel. The engineering deliverables are organized in a completely different way following the build strategy and focusing on the production work. This phase is not part of the engineering design and will not be addressed further in this document.

PHILOSOPHY

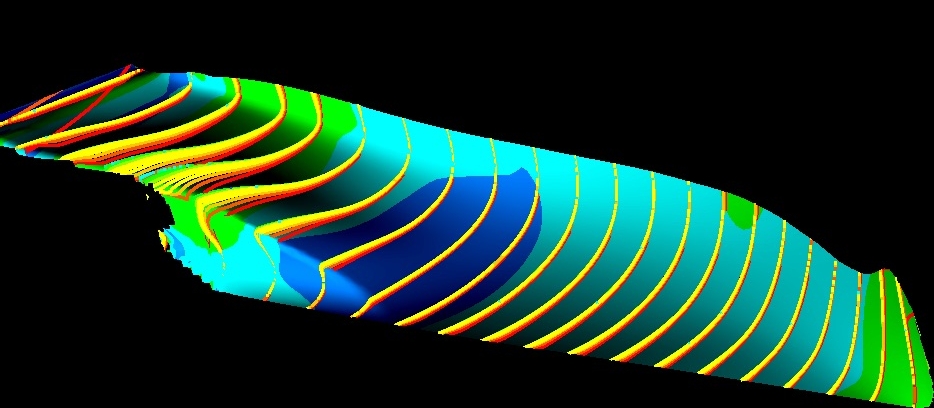

Although the objectives of each phase are different, the design philosophy followed in Concept, Contract, and Functional Design is identical. During each phase, all of the key design elements are addressed on or more times, creating an iterative “design spiral” (see Figure 1). During these phases, engineering develops and integrated vessel to meet a set of defined requirements. This necessitates analyzing the vessel systems in greater detail during each successive phase. Implementing the design spiral requires discipline. If we start from a blank sheet of paper, it is appropriate to iterate the design spiral several times even during concept design, with a number of false starts possible before hitting on the proper solution. If we start from a set of construction drawings needing only minor modifications, we still need to make at least one loop around the design spiral to ensure that the proposed design meets the mission requirements.

It is crucial to investigate each element of the design spiral to insure an integrated design. The elements flow from the prior elements, developing and validating the design as the design spiral progresses. This does not infer that as new information is developed, retreating a few steps is inappropriate. Backing design spiral and skipping elements is inappropriate and could lead to design errors. Elements of the design spiral may be addressed simultaneously but the risk of rework due to design errors increases.

The key design elements to be addressed in each of the first three phases are:

1. Mission & Owner Requirements

2. Mission Systems

3. Principal Form

4. Powering

5. Lines and Hydrostatics

6. General Arrangements and Outfitting

7. Freeboards and Stability Envelope

8. Capacities and Areas

9. Machinery, Arrangements, and Distributive Systems

10. Structure

11. Weight Estimate

12. Trim and Stability

13. Producibility

14. Cost Engineering

All of the elements are inter-related by the fact that the vessel must embody and integrate each of them. Therefore, changing one element has unavoidable consequences on the others. The objective of the design spiral is to integrate the elements until those consequences are minimal. Once that point is reached, Functional Design is complete and Production Design can begin with minimal design risk. Proceeding with Production Design before all key elements are integrated introduces the risk that unforeseen consequences will cause rework of Production Design deliverables and the vessel when discovered.

Mission and Owner Requirements

The mission requirements define the vessel’s reason for existence and any other owner requirements. The mission requirements are initially defined by the customer but their final form is the result of the design process.

Mission Systems

These are any parts of the vessel which are present only to allow accomplishment of the mission. This includes such widely varying things as cargo rails and bulk mud tanks on supply vessels, cargo handling gear and cell guides on a container vessel, laboratories and electronic systems on a research vessel, and the guest accommodations on a yacht or passenger vessel.

Principal Form

The principal form is the vessel’s overall envelope. It includes the hull type (i.e. displacement, planing, catamaran, etc.) and the principal dimensions.

Powering

Powering defines the propulsion system, including prime mover, power transmission (gear and shafting), and propulsor.

Lines and Hydrostatics

The lines define the three dimensional geometry of the vessel’s hull. Hydrostatics are checked to confirm compliance with requirements.

General Arrangements and Outfitting

The general arrangements subdivide the principal form into internal and external spaces. They locate bulkheads, decks, major openings, principal equipment, and mission critical components. Outfitting defines the non-structural and non-mechanical elements of the vessel.

Freeboards and Stability Envelope

Freeboards and Stability are calculated based on regulatory and mission requirements to determine a stability envelope to be used for design verification.

Capacities and Areas

The capacities and areas are the tank capacities, cargo areas, cargo capacity, and any other area or volume requirements.

Machinery Arrangements and Distributive Systems

The machinery arrangements locate all of the vessel’s machinery and equipment. The distributive systems include piping, HVAC, and electrical systems.

Structure

This element defines the vessel’s structure.

Weight Estimate

The weight estimate defines the weight and center of gravity of the vessel’s lightship and of any variable loads.

Trim and Stability

This element compares the Weight Estimate and the Freeboard and Stability Envelope to verify design requirements have been met.

Producibility

This step examines the design to maximize production efficiency considering the manufacturing capabilities and practices of the construction facility.

Cost Engineering

This element analyzes technical alternatives between equipment, make or buy decisions, and other factors affecting the vessel’s cost.

APPLICATION

As noted above, the design maturity increases as we change phases. However, in each of the first three phases, each element is investigated at least once. The depth of the investigation and the integration of the elements increases through each phase.

Concept Design

Concept design is a feasibility study to determine fundamental aspects of the design addressing high level requirements, suitable for determining whether to move to the next level of design development. Elements for Concept Design will be brief and will contain only sketchy detail. They are usually taken from design standards, curves, formulas, other designs or historical data, and are often parametrically derived. This phase explicitly addresses each of the key design elements, identifying what data was used in the concept design, its source, and the justification for its use.

Contract Design

Contract Design develops the vessel design to a much greater extent. Key design elements are defined in Contract Design by engineering analysis, calculations and design standards. The mission and owner requirements are defined in detail. The primary characteristics of the fourteen key elements would not be expected to change in future design development. The completed contract design provides a clear definition of a vessel meeting the mission and owner requirements.

Functional Design

Functional Design is much more extensive than Concept or Contract Design. Functional Design integrates the vessel and all systems to meet the mission and owner requirements. The design details of the fourteen key elements will not change during Production Design. This is achieved by iterating the design spiral, until all systems and components have been designed, selected, and integrated.